In today's competitive manufacturing world, having the right equipment is essential to ensuring smooth production processes and high-quality output. One key piece of equipment in the packaging sector is the stretch film machine. Stretch film plays an integral role in the protection and stability of packaged goods, making it an essential part of manufacturing and distribution processes. Investing in a cast stretch film machine offers numerous advantages for your manufacturing facility. In this article, we will explore how a stretch film machine enhances efficiency, saves costs, and improves product protection.

The Importance of Stretch Film in Manufacturing

Stretch film is used to wrap products securely for shipping, protecting them from moisture, dirt, and physical damage during transit. The film is designed to cling tightly to products, ensuring they stay in place and are less likely to be damaged. A stretch film machine helps automate the production process of this protective packaging material, providing businesses with the ability to produce high-quality stretch films in large volumes.

The cast stretch film machine is one of the most popular types of stretch film machines used in the industry. It uses a cast film extrusion process to produce high-quality, transparent stretch films, providing excellent clarity and stretchability. By investing in the right stretch film machine, businesses can streamline their packaging processes, increase output, and reduce labor costs.

How a Stretch Film Machine Improves Packaging Efficiency

A stretch film machine significantly improves packaging efficiency in manufacturing by automating the stretch film production process. Traditional manual methods of producing stretch film can be time-consuming and inconsistent. However, with an automated stretch film machine, manufacturers can produce high-quality stretch films at much faster rates and with greater precision.

By automating the process, manufacturers can reduce the need for manual labor, which decreases the chance of human error and allows workers to focus on other critical tasks. The machine can also produce films in various thicknesses, lengths, and widths to accommodate different types of products. As a result, businesses can handle a larger volume of orders and reduce the time it takes to wrap and protect products.

Advantages of Cast Stretch Film Machines for Manufacturing

The cast stretch film machine offers specific benefits for manufacturers that require high-quality stretch film for packaging. Cast stretch films are known for their superior transparency, high gloss, and excellent puncture resistance. These properties make cast films ideal for wrapping delicate or high-value products that require both protection and visibility.

One of the key advantages of the cast stretch film machine is its ability to produce films with enhanced stretchability. The machine allows manufacturers to create films that can stretch significantly without breaking, providing a tight, secure fit around products. This not only ensures product safety during transit but also reduces the amount of film needed per package, leading to material savings.

Another benefit of the cast stretch film machine is its ability to create films that are resistant to UV light and environmental factors. This is crucial for businesses that deal with products that need to be stored or transported for long periods, as the stretch film will help protect against degradation from sunlight and moisture.

Comparing Fully Automatic and Semi-Automatic Stretch Film Machines

When selecting a stretch film machine for your manufacturing facility, one important consideration is whether to invest in a fully automatic or semi-automatic machine. Both types of machines offer distinct advantages depending on your production needs and goals. Below is a comparison of the two:

Feature | Fully Automatic Stretch Film Machine | Semi-Automatic Stretch Film Machine |

Automation Level | High level of automation, requires minimal human intervention. | Requires more manual input for adjustments and operation. |

Production Speed | Faster production speeds, ideal for high-volume operations. | Slower production speeds, better for small to medium production volumes. |

Film Quality | Consistently high-quality film with precise control over thickness and stretchability. | Slight variations in film quality due to manual adjustments. |

Labor Requirements | Minimal labor required for operation, saving on workforce costs. | Requires more manual labor and oversight. |

Flexibility | Limited flexibility in handling a wide variety of film types or sizes. | More flexible and customizable for different film types and production runs. |

Maintenance | Requires more advanced maintenance due to the complexity of the system. | Easier and less costly to maintain. |

Suitability for Production Scale | Best for high-volume, continuous production lines. | Ideal for smaller-scale operations or companies with varying production demands. |

Choosing the Right Stretch Film Machine for Your Facility

Choosing between a fully automatic and semi-automatic stretch film machine largely depends on the scale of your production and the level of automation you require. If you are looking for a high-speed solution for large-scale production, a fully automatic stretch film machine would be the best option. These machines require minimal human intervention and can operate continuously, ensuring that your production line runs efficiently.

However, for smaller operations or businesses that require flexibility in handling different types of films, a semi-automatic stretch film machine may be more suitable. While these machines may require more manual input, they offer greater customization options and are typically easier to maintain.

In either case, investing in a stretch film machine will streamline your packaging processes, reduce labor costs, and improve the overall efficiency of your manufacturing facility. By selecting the right machine for your needs, you can ensure that your products are securely packaged and ready for shipping with minimal effort and maximum output.

References:

Packaging Industry Trends

Film Manufacturing Insights

Stretch Film Packaging Innovations

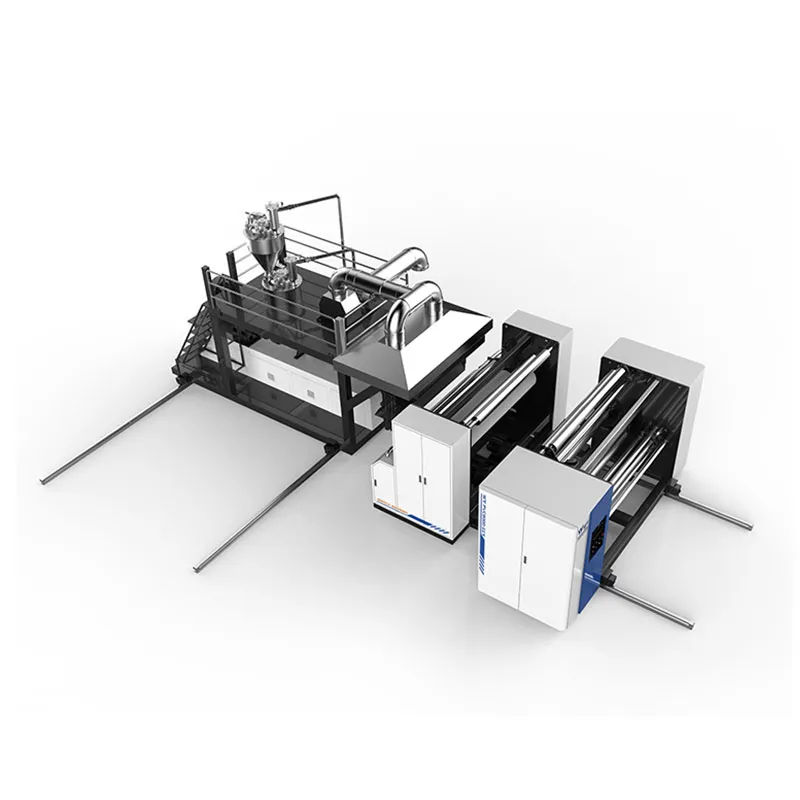

2400MM Full-Automatic Stretch Film Production Line

2400MM Full-Automatic Stretch Film Production Line

1850MM Three Five Layer Co-extrusion Stretch Film Production Line

1850MM Three Five Layer Co-extrusion Stretch Film Production Line

1250mm Automatic High Speed Three/Five Layer Co-extrusion Stretch Film Production Line

1250mm Automatic High Speed Three/Five Layer Co-extrusion Stretch Film Production Line

1250MM Fully Automatic High Speed Two/Three-layer Stretch Film Machinery

1250MM Fully Automatic High Speed Two/Three-layer Stretch Film Machinery

Four-Shafts Roll Change Automatic Cast Stretch Film Production Line

Four-Shafts Roll Change Automatic Cast Stretch Film Production Line

New Three-Shafts Automatic Stretch Film Production Line

New Three-Shafts Automatic Stretch Film Production Line

Full-Automatic Back Rest Stretch Film Production Line

Full-Automatic Back Rest Stretch Film Production Line

2400MM Cling Film Production Line

2400MM Cling Film Production Line

1850MM Cling Film Production Line

1850MM Cling Film Production Line

1250MM Cling Film Production Line

1250MM Cling Film Production Line

Fully Automatic Stretch/Cling Film Rewinding Machine

Fully Automatic Stretch/Cling Film Rewinding Machine

Semi-automatic High Speed Aluminum Foil Rewinding Machine

Semi-automatic High Speed Aluminum Foil Rewinding Machine

High Speed Pre Stretch/Cling Film Rewinding Machine

High Speed Pre Stretch/Cling Film Rewinding Machine

Semi-automatic Stretch/Cling Film Rewinding and Slitting Machine

Semi-automatic Stretch/Cling Film Rewinding and Slitting Machine

New Design Fully Automatic High Speed Rewinding Machine

New Design Fully Automatic High Speed Rewinding Machine

Five Shafts Fully Automatic Stretch/Cling Film Rewinding Machine

Five Shafts Fully Automatic Stretch/Cling Film Rewinding Machine