When it comes to packaging and film production, the choice of equipment plays a critical role in determining the efficiency, quality, and speed of your operation. One of the most important machines in film production is the film rewinder, which ensures that the film is wound tightly and evenly onto rolls for further processing or packaging. Depending on the scale of your production, you will need to choose between automatic and semi-automatic film rewinders. This article will guide you through the process of choosing the right film rewinder for your manufacturing needs, with a particular focus on the differences between fully automatic and semi-automatic film rewinding machines.

Understanding the Role of Film Rewinders

A film rewinder is a specialized machine used to wind film into rolls after the film has been processed or manufactured. This could include films like PVC, PE, or other types of packaging materials. In various industries such as food packaging, medical supplies, and electronics, the quality of film winding is critical to the success of the final product. Ensuring that the film is wound properly can prevent defects, reduce waste, and increase operational efficiency.

The choice between a fully automatic and semi-automatic film rewinder largely depends on the production scale and the level of automation desired. Each type offers distinct advantages depending on your specific needs.

Key Considerations for Choosing the Right Film Rewinder

When deciding on the best film rewinder machine for your production line, several factors must be taken into account. These include the volume of production, the type of film used, the required winding speed, and the overall efficiency of the machine. The type of rewinder you choose will directly affect your output rate and the consistency of the winding process.

The first key factor to consider is the volume of production. If your manufacturing process involves large volumes of film production on a daily basis, an automatic film rewinder is likely the best option. These machines offer fast, high-speed performance and can run without requiring frequent operator intervention. On the other hand, if your production is smaller-scale or requires flexibility in the types of films processed, a semi-automatic film rewinder might be more suitable.

Another factor to consider is the type of film. Some films may require specific tension settings, winding speeds, or customized adjustments to ensure a smooth and uniform roll. Understanding the specific requirements of the film you are using will help in selecting the right rewinder.

Comparing Fully Automatic and Semi-Automatic Film Rewinders

Choosing between a fully automatic and a semi-automatic film rewinder largely depends on your production needs, efficiency goals, and flexibility requirements. To help you make the right decision, here is a comparison between these two types of film rewinders:

Feature | Fully Automatic Film Rewinder | Semi-Automatic Film Rewinder |

Level of Automation | High automation with minimal manual intervention. | Requires manual adjustments and intervention during operation. |

Speed and Efficiency | Offers high-speed winding for large production volumes. | Slower than automatic, but suitable for smaller, more varied runs. |

Precision and Control | Provides precise tension control, speed regulation, and automated adjustments. | Requires manual control of tension and winding speed. |

Flexibility | Limited flexibility; primarily for large, continuous runs of uniform film. | More flexible for handling different types and sizes of film rolls. |

Production Scale | Ideal for high-volume, continuous production lines. | Best for smaller-scale operations or custom runs. |

Maintenance Needs | Requires more sophisticated maintenance due to automation. | Easier to maintain, with simpler systems to troubleshoot. |

Labor Requirements | Minimal labor required due to automation. | Requires more manual labor for operation and adjustments. |

Advantages of Fully Automatic Film Rewinders

Fully automatic film rewinders are designed for high-volume production lines where speed, precision, and minimal downtime are essential. These machines are equipped with advanced controls that automatically adjust winding tension, speed, and other settings to optimize the process. As a result, automatic film rewinders significantly reduce the amount of manual labor required, enabling manufacturers to focus on other areas of the production process.

The automatic stretch film rewinder processes large quantities of film rolls quickly with minimal operator intervention. This high level of automation ensures that the film is wound precisely, reducing the risk of errors such as uneven winding or tension inconsistencies. These machines are ideal for large-scale operations where high-speed production and consistency are vital.

Advantages of Semi-Automatic Film Rewinders

Semi-automatic film rewinders, on the other hand, provide more flexibility and are ideal for smaller or more diverse production runs. While they do require more manual intervention compared to their fully automatic counterparts, they offer operators greater control over the winding process. Semi-automatic machines are easier to adjust for different film types, thicknesses, and roll sizes, making them a versatile option for businesses with varied production requirements.

These machines are typically easier to maintain, as their simpler designs mean fewer complex components that could require service. Semi-automatic film rewinders are a great choice for businesses that don't require continuous, high-speed production but still need reliable winding capabilities for smaller runs.

Conclusion: Which Film Rewinder Is Right for You?

The choice between a fully automatic and semi-automatic film rewinder depends on your specific production needs. For high-volume operations that require speed, efficiency, and precision, a fully automatic film rewinder is the ideal choice. It offers the highest level of automation, ensuring minimal labor input and maximum output. However, for businesses that prioritize flexibility and manage smaller or diverse production volumes, a semi-automatic film rewinder can provide a more cost-effective solution.

In either case, selecting the right film rewinder will depend on your production scale, the types of films being processed, and your need for automation. Understanding the differences between these two types of rewinders is key to making an informed decision that aligns with your business's needs.

References:

Packaging World: Film Packaging

Modern Manufacturing Technology

Advanced Packaging Solutions

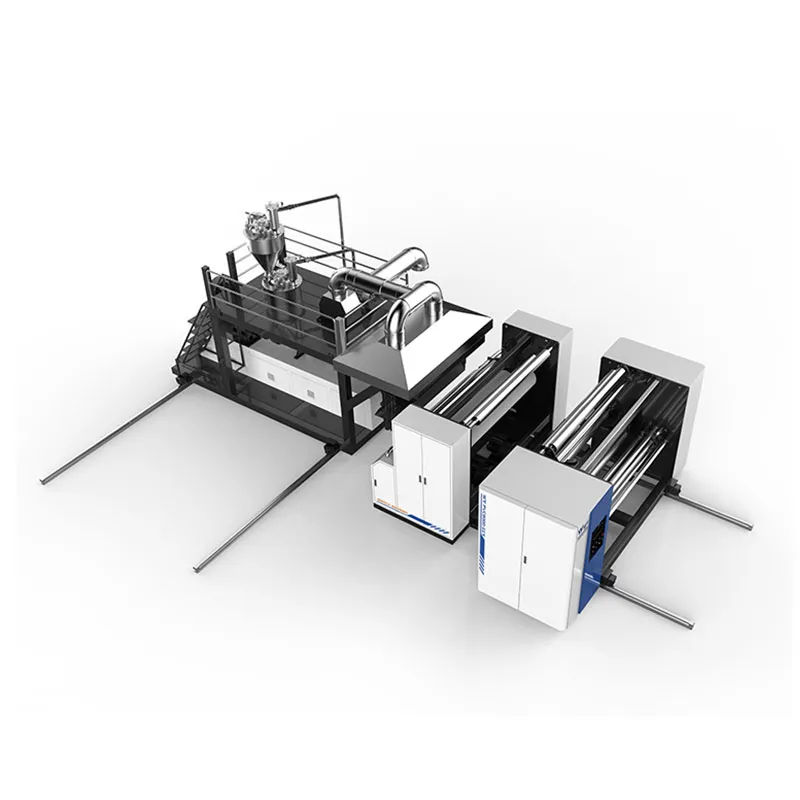

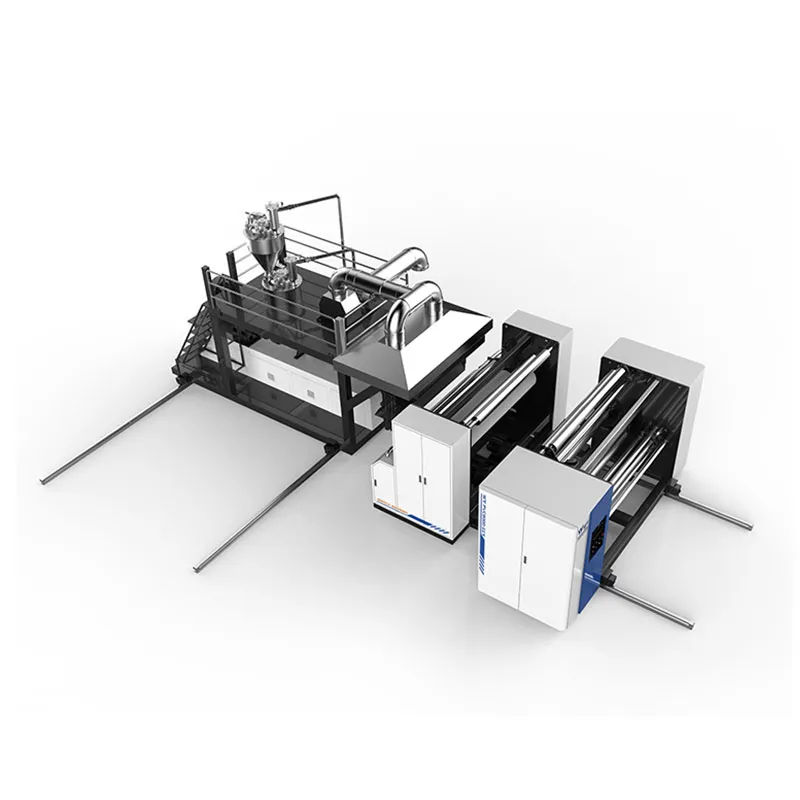

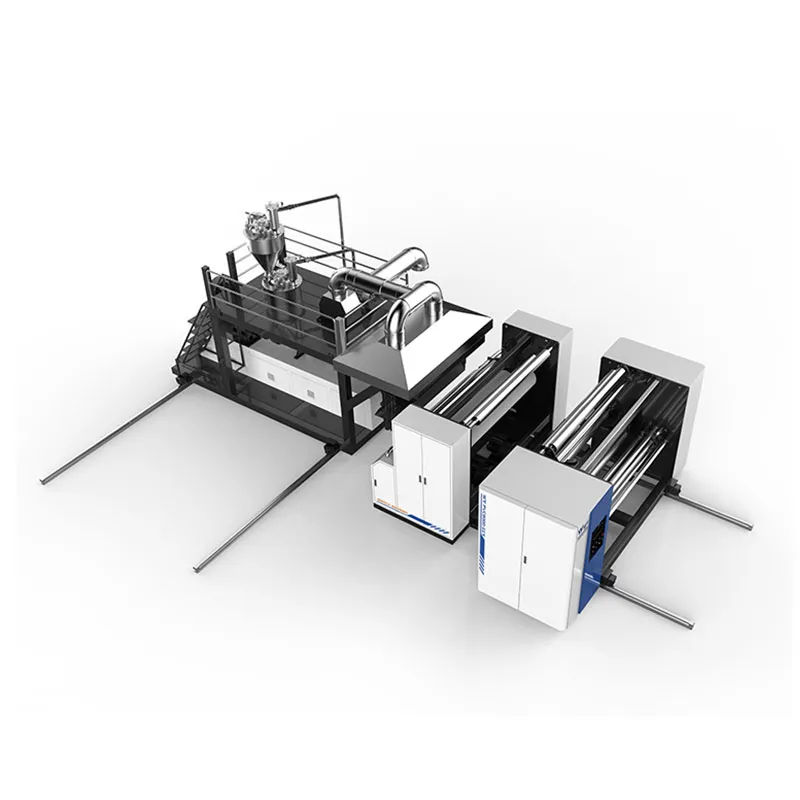

2400MM Full-Automatic Stretch Film Production Line

2400MM Full-Automatic Stretch Film Production Line

1850MM Three Five Layer Co-extrusion Stretch Film Production Line

1850MM Three Five Layer Co-extrusion Stretch Film Production Line

1250mm Automatic High Speed Three/Five Layer Co-extrusion Stretch Film Production Line

1250mm Automatic High Speed Three/Five Layer Co-extrusion Stretch Film Production Line

1250MM Fully Automatic High Speed Two/Three-layer Stretch Film Machinery

1250MM Fully Automatic High Speed Two/Three-layer Stretch Film Machinery

Four-Shafts Roll Change Automatic Cast Stretch Film Production Line

Four-Shafts Roll Change Automatic Cast Stretch Film Production Line

New Three-Shafts Automatic Stretch Film Production Line

New Three-Shafts Automatic Stretch Film Production Line

Full-Automatic Back Rest Stretch Film Production Line

Full-Automatic Back Rest Stretch Film Production Line

2400MM Cling Film Production Line

2400MM Cling Film Production Line

1850MM Cling Film Production Line

1850MM Cling Film Production Line

1250MM Cling Film Production Line

1250MM Cling Film Production Line

Fully Automatic Stretch/Cling Film Rewinding Machine

Fully Automatic Stretch/Cling Film Rewinding Machine

Semi-automatic High Speed Aluminum Foil Rewinding Machine

Semi-automatic High Speed Aluminum Foil Rewinding Machine

High Speed Pre Stretch/Cling Film Rewinding Machine

High Speed Pre Stretch/Cling Film Rewinding Machine

Semi-automatic Stretch/Cling Film Rewinding and Slitting Machine

Semi-automatic Stretch/Cling Film Rewinding and Slitting Machine

New Design Fully Automatic High Speed Rewinding Machine

New Design Fully Automatic High Speed Rewinding Machine

Five Shafts Fully Automatic Stretch/Cling Film Rewinding Machine

Five Shafts Fully Automatic Stretch/Cling Film Rewinding Machine