In today's fast-paced food industry, packaging plays a crucial role in ensuring product quality, safety, and shelf life. One of the most innovative solutions for food packaging is the PVC cling film machine, which has transformed how food is wrapped, preserved, and transported. This article explores how PVC cling film machines revolutionize food packaging by offering enhanced protection, improving convenience, and supporting sustainability.

The Role of PVC Cling Film in Food Packaging

PVC cling film has been a staple in the food packaging industry due to its ability to provide an airtight, moisture-resistant seal that preserves food for longer periods. The PVC cling film machine is designed to produce this versatile material at a high production rate, allowing businesses to meet the ever-growing demand for packaged food. This packaging solution not only improves the freshness of food by protecting it from contaminants but also extends the shelf life of perishable goods.

The cling film produced by these machines can easily wrap a variety of food items, from fresh fruits and vegetables to meats, cheeses, and bakery products. The transparency of PVC cling film allows for easy product identification while offering an extra layer of protection against spoilage, oxidation, and moisture loss. This makes it an ideal choice for preserving food quality while ensuring its safety during transportation and storage.

Features and Functionality of PVC Cling Film Machines

PVC cling film machines are designed with advanced technology that enhances production efficiency and product quality. These machines are capable of producing high-quality cling film rolls in various thicknesses and lengths, depending on the requirements of the packaging industry. The machines operate through a process that includes extrusion, cooling, and winding to create uniform rolls of PVC film. The high level of automation ensures that the process is both time-efficient and cost-effective.

One of the key features of PVC cling film machines is their ability to produce stretchable and flexible film. This stretchability allows the cling film to conform tightly to the surface of packaged food, ensuring that it adheres to the shape of the product and provides a secure, protective wrap. Additionally, modern PVC cling film machines are equipped with precision cutting mechanisms to ensure consistent film lengths and widths, making them highly adaptable to various packaging needs.

How PVC Cling Film Machines Improve Food Preservation

The ability of PVC cling film to preserve food is one of the key reasons it remains a preferred packaging material. The cling film produced by these machines helps extend the freshness of food by preventing the growth of bacteria and mold, which can occur when food is exposed to air. By creating a tight seal around food products, the film minimizes exposure to oxygen, which can cause spoilage and deterioration.

Additionally, the moisture-resistant properties of PVC cling film help maintain the natural moisture content of food, preventing dehydration and the loss of flavor. For products like fruits, vegetables, and meats, this is particularly important, as moisture loss can lead to wilting, shriveling, and loss of texture. With the use of PVC cling film machines, businesses can produce large quantities of high-quality packaging that ensures food stays fresh for longer, reducing waste and improving customer satisfaction.

The Benefits of Using PVC Cling Film Machines in Food Packaging

The PVC cling film machine has several advantages that make it a vital tool in modern food packaging. One of the primary benefits is the efficiency and speed of production. These machines are capable of producing large quantities of cling film in a short amount of time, helping businesses keep up with high demand. Furthermore, the film produced is lightweight, reducing packaging costs and improving transportation efficiency.

Another significant advantage is the versatility of PVC cling film. Unlike traditional packaging materials like rigid plastic containers or glass jars, PVC cling film can be used for a wide range of food products, including items with irregular shapes. The cling film can easily mold to the contours of different products, making it a flexible and adaptable choice for food packaging.

In addition to preserving food and improving packaging efficiency, PVC cling film machines are also contributing to sustainability efforts. The ability to produce thinner, more efficient rolls of cling film reduces waste during production and ensures that packaging materials are used more effectively. Moreover, many manufacturers are exploring ways to make PVC cling film recyclable, which could further reduce its environmental impact.

Comparing PVC Cling Film Machines with Other Packaging Methods

While PVC cling film machines offer numerous benefits, it is essential to understand how they compare to other packaging methods in terms of performance, versatility, and environmental impact. Below is a comparison of PVC cling film packaging and other popular packaging solutions in the food industry:

Feature | PVC Cling Film | Other Packaging Methods (e.g., Plastic Containers, Glass Jars) |

Packaging Flexibility | Highly flexible, molds to various product shapes. | Less flexible, limited to uniform product shapes. |

Shelf Life Extension | Extends freshness by preventing moisture loss and contamination. | Less effective in preserving food freshness and moisture. |

Transparency | Transparent for easy product identification. | Often opaque, making it harder to view contents. |

Environmental Impact | Some concerns about recyclability, but advancements are being made. | More recyclable options are available (e.g., glass). |

Speed of Production | Fast production with high automation. | Slower production for other packaging methods. |

This comparison highlights that while PVC cling film machines provide flexibility, speed, and preservation benefits, other packaging methods may be more suitable for products that require rigid containment or for companies looking for fully recyclable solutions.

Conclusion

The PVC cling film machine has significantly changed the way food packaging is done, offering enhanced protection, improved efficiency, and the ability to extend the shelf life of various food products. By ensuring that food remains fresh, safe, and hygienic, these machines play a crucial role in modern food production and distribution. As the demand for sustainable and efficient packaging continues to grow, PVC cling film machines will likely remain an essential part of the food packaging industry.

References:

Food Packaging Solutions

Sustainable Packaging Innovations

PVC Cling Film Manufacturing Techniques

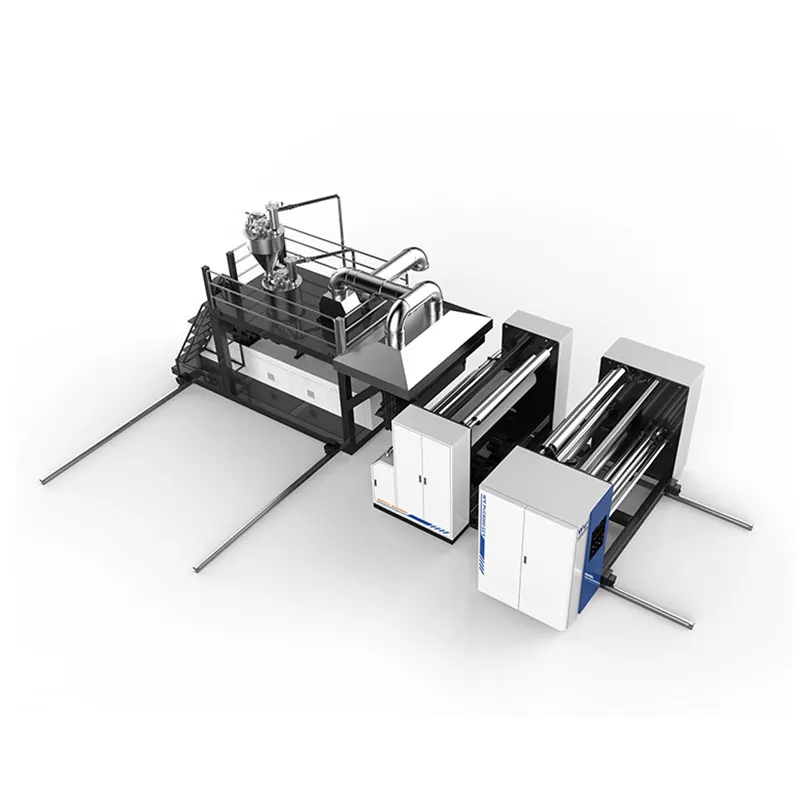

2400MM Full-Automatic Stretch Film Production Line

2400MM Full-Automatic Stretch Film Production Line

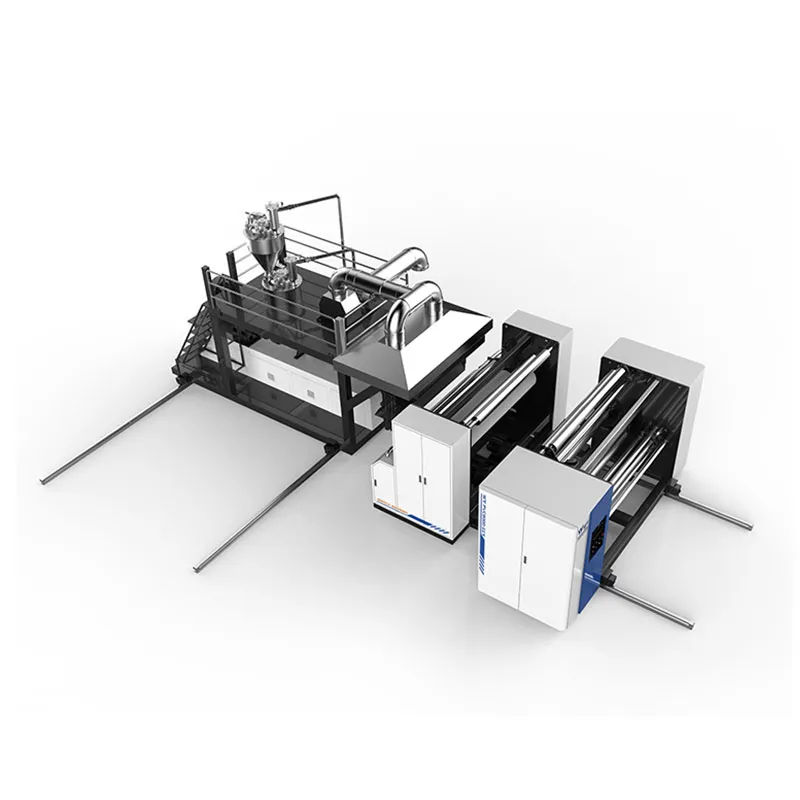

1850MM Three Five Layer Co-extrusion Stretch Film Production Line

1850MM Three Five Layer Co-extrusion Stretch Film Production Line

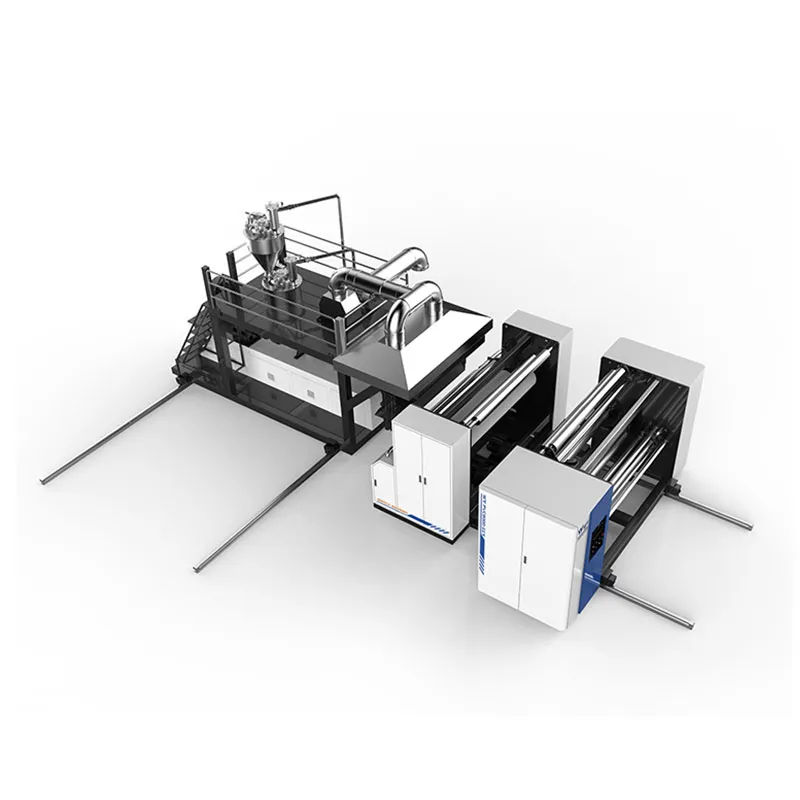

1250mm Automatic High Speed Three/Five Layer Co-extrusion Stretch Film Production Line

1250mm Automatic High Speed Three/Five Layer Co-extrusion Stretch Film Production Line

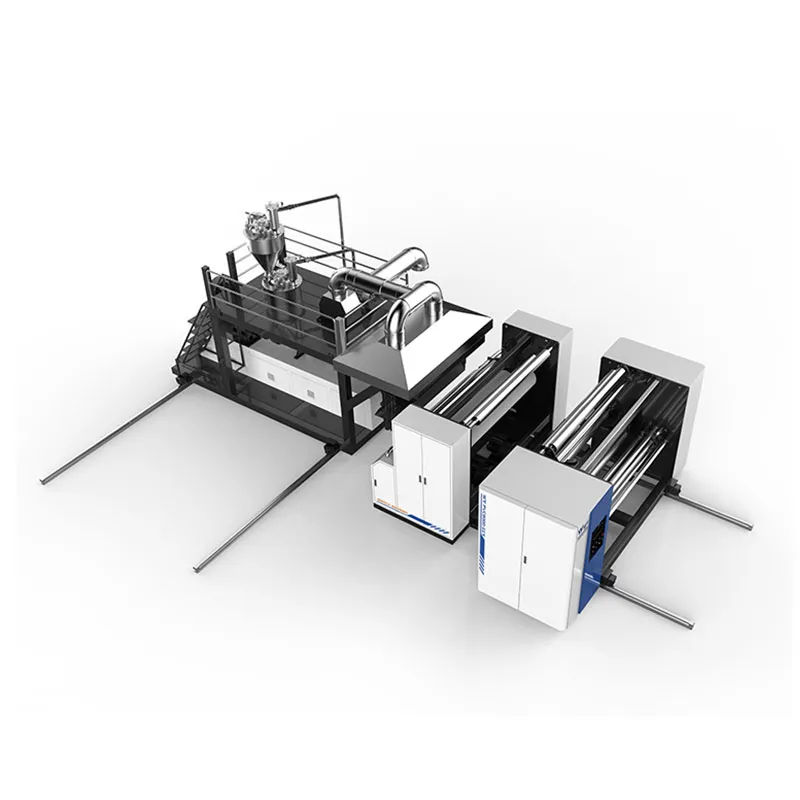

1250MM Fully Automatic High Speed Two/Three-layer Stretch Film Machinery

1250MM Fully Automatic High Speed Two/Three-layer Stretch Film Machinery

Four-Shafts Roll Change Automatic Cast Stretch Film Production Line

Four-Shafts Roll Change Automatic Cast Stretch Film Production Line

New Three-Shafts Automatic Stretch Film Production Line

New Three-Shafts Automatic Stretch Film Production Line

Full-Automatic Back Rest Stretch Film Production Line

Full-Automatic Back Rest Stretch Film Production Line

2400MM Cling Film Production Line

2400MM Cling Film Production Line

1850MM Cling Film Production Line

1850MM Cling Film Production Line

1250MM Cling Film Production Line

1250MM Cling Film Production Line

Fully Automatic Stretch/Cling Film Rewinding Machine

Fully Automatic Stretch/Cling Film Rewinding Machine

Semi-automatic High Speed Aluminum Foil Rewinding Machine

Semi-automatic High Speed Aluminum Foil Rewinding Machine

High Speed Pre Stretch/Cling Film Rewinding Machine

High Speed Pre Stretch/Cling Film Rewinding Machine

Semi-automatic Stretch/Cling Film Rewinding and Slitting Machine

Semi-automatic Stretch/Cling Film Rewinding and Slitting Machine

New Design Fully Automatic High Speed Rewinding Machine

New Design Fully Automatic High Speed Rewinding Machine

Five Shafts Fully Automatic Stretch/Cling Film Rewinding Machine

Five Shafts Fully Automatic Stretch/Cling Film Rewinding Machine