In today's competitive manufacturing environment, the role of advanced machinery in ensuring efficiency and precision cannot be overstated. One such critical machine is the high speed rewinding machine, which has become indispensable in modern production lines, especially for industries dealing with films and rolls. Wintech's cutting-edge high speed rewinding machines exemplify the innovation driving industries toward greater productivity and quality.

What is a High speed rewinding machine?

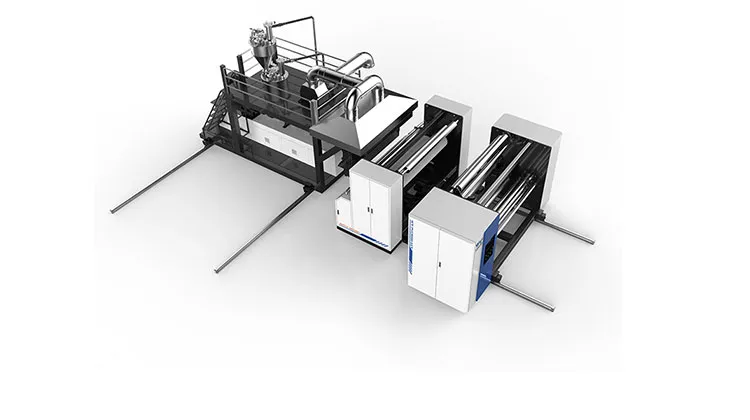

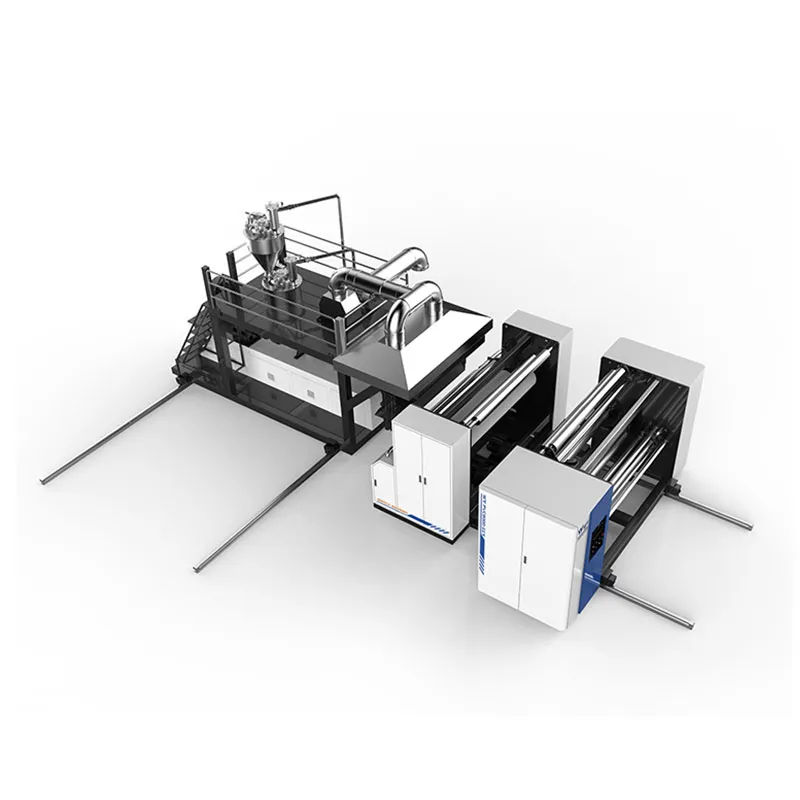

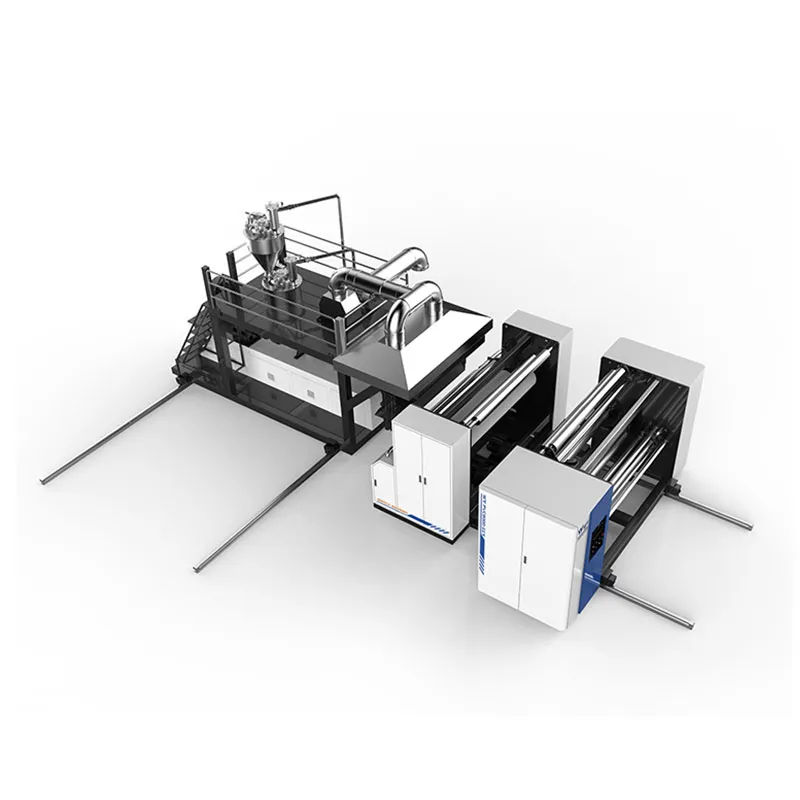

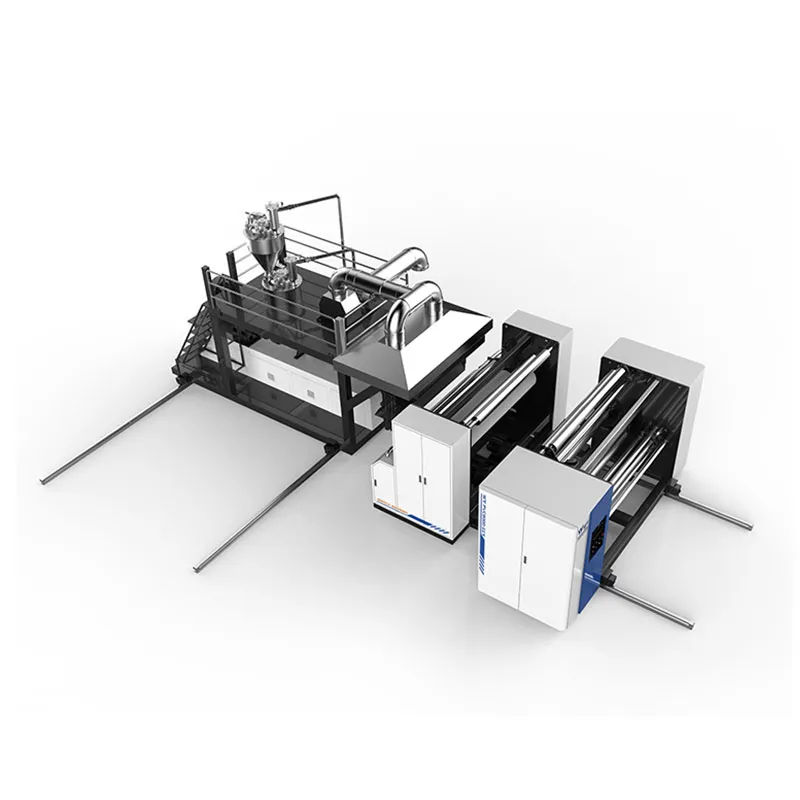

A high speed rewinding machine is a specialized piece of equipment designed to rewind various materials, such as stretch films, onto cores at a significantly high speed. This process is crucial in industries such as packaging, textiles, and paper production. By efficiently rewinding materials into tight, uniform rolls, these machines ensure that the products are ready for further processing or shipping, thus facilitating faster turnaround times in production lines. Wintech's high speed rewinding machines stand out for their precision and reliability, ensuring consistent performance even in high-demand environments.

Key Features of Wintech's High speed rewinding machines

Wintech's high speed rewinding machines come equipped with state-of-the-art features that set them apart from traditional rewinding equipment. These machines are designed to handle high-speed operations without compromising on the quality of the rewind. A significant feature of these machines is their ability to maintain excellent tension control, ensuring that the material being rewound is not subject to any defects such as wrinkles, stretches, or tears. Wintech's advanced tension control system guarantees that even at high speeds, the material is rewound smoothly, reducing the chances of production interruptions.

Additionally, Wintech's machines incorporate precision sensors and automation systems that optimize the rewinding process. These technologies allow for quick adjustments to be made to the rewinding parameters, such as speed, tension, and pressure, without needing manual intervention. This not only enhances the efficiency of the production process but also minimizes human error, contributing to more consistent product quality.

High speed rewinding machines vs. Traditional Rewinding Machines

When comparing high speed rewinding machines with their traditional counterparts, the differences become immediately apparent. Traditional rewinding machines often struggle to maintain high levels of accuracy and consistency when operating at high speeds. This can lead to defective products, delays in production, and increased waste. In contrast, high speed rewinding machines, such as those offered by Wintech, ensure that the quality of the product remains consistent even during high-speed operations. They are designed for fast-paced environments and can handle large volumes of materials efficiently.

Feature | Traditional Rewinding Machine | High speed rewinding machine |

Speed | Slower, less efficient | High-speed, optimized for speed |

Tension Control | Less precise, can cause defects | Advanced control for uniformity |

Automation | Manual adjustments | Fully automated, minimal manual intervention |

Consistency of Output | Can vary with speed | High precision, consistent output |

Material Handling | Less efficient at high speeds | Capable of handling various materials without issues |

This table highlights the significant advantages that high speed rewinding machines offer over their traditional counterparts, particularly in high-demand production lines. The automation and advanced control systems of modern rewinding machines make them a far more efficient choice for businesses looking to scale their operations without compromising quality.

The Role of High speed rewinding machines in the Stretch Film Industry

In industries like the production of stretch films, where the quality of the film is paramount, high speed rewinding machines play a crucial role in ensuring product integrity. Stretch films need to be wound tightly to prevent damage during transport and storage, and any inconsistency in the winding process can lead to waste or defective products. Wintech's high speed rewinding machines are particularly effective in handling stretch films, ensuring they are wound in perfect layers with uniform tension, preserving their strength and functionality.

Moreover, the increased speed of these machines reduces production time, allowing manufacturers to meet the growing demand for stretch films, particularly in the packaging industry. This makes the machines an essential part of modern production lines, helping companies keep up with the demands of a fast-paced market.

The Impact on Overall Production Efficiency

The implementation of high speed rewinding machines in modern production lines offers several key benefits that enhance overall production efficiency. One of the most significant impacts is the reduction in downtime. By operating at high speeds without sacrificing precision, these machines can process large quantities of material in less time. This directly translates into higher output and better utilization of manufacturing resources.

Another major benefit is the reduction in the need for manual labor. With automated systems controlling key parameters like speed, tension, and pressure, operators can focus on monitoring the process and addressing any potential issues, rather than manually adjusting settings. This level of automation significantly reduces human error and ensures a more efficient production cycle.

In addition to speed and automation, the consistent quality of the output also reduces waste and rework. As high speed rewinding machines ensure that the material is wound uniformly, the likelihood of defective products is minimized. This results in less material wastage, fewer returns, and greater customer satisfaction.

Conclusion

In conclusion, high speed rewinding machines are vital components of modern production lines, especially in industries that require precision and high-volume output. Wintech's machines exemplify the best in high-speed rewinding technology, offering a level of automation, control, and efficiency that is critical to maintaining competitiveness in today's manufacturing environment. By integrating these advanced machines into production lines, companies can increase efficiency, reduce waste, and improve overall product quality, ensuring they stay ahead in the fast-evolving industrial landscape.

References:

2400MM Full-Automatic Stretch Film Production Line

2400MM Full-Automatic Stretch Film Production Line

1850MM Three Five Layer Co-extrusion Stretch Film Production Line

1850MM Three Five Layer Co-extrusion Stretch Film Production Line

1250mm Automatic High Speed Three/Five Layer Co-extrusion Stretch Film Production Line

1250mm Automatic High Speed Three/Five Layer Co-extrusion Stretch Film Production Line

1250MM Fully Automatic High Speed Two/Three-layer Stretch Film Machinery

1250MM Fully Automatic High Speed Two/Three-layer Stretch Film Machinery

Four-Shafts Roll Change Automatic Cast Stretch Film Production Line

Four-Shafts Roll Change Automatic Cast Stretch Film Production Line

New Three-Shafts Automatic Stretch Film Production Line

New Three-Shafts Automatic Stretch Film Production Line

Full-Automatic Back Rest Stretch Film Production Line

Full-Automatic Back Rest Stretch Film Production Line

2400MM Cling Film Production Line

2400MM Cling Film Production Line

1850MM Cling Film Production Line

1850MM Cling Film Production Line

1250MM Cling Film Production Line

1250MM Cling Film Production Line

Fully Automatic Stretch/Cling Film Rewinding Machine

Fully Automatic Stretch/Cling Film Rewinding Machine

Semi-automatic High Speed Aluminum Foil Rewinding Machine

Semi-automatic High Speed Aluminum Foil Rewinding Machine

High Speed Pre Stretch/Cling Film Rewinding Machine

High Speed Pre Stretch/Cling Film Rewinding Machine

Semi-automatic Stretch/Cling Film Rewinding and Slitting Machine

Semi-automatic Stretch/Cling Film Rewinding and Slitting Machine

New Design Fully Automatic High Speed Rewinding Machine

New Design Fully Automatic High Speed Rewinding Machine

Five Shafts Fully Automatic Stretch/Cling Film Rewinding Machine

Five Shafts Fully Automatic Stretch/Cling Film Rewinding Machine