-

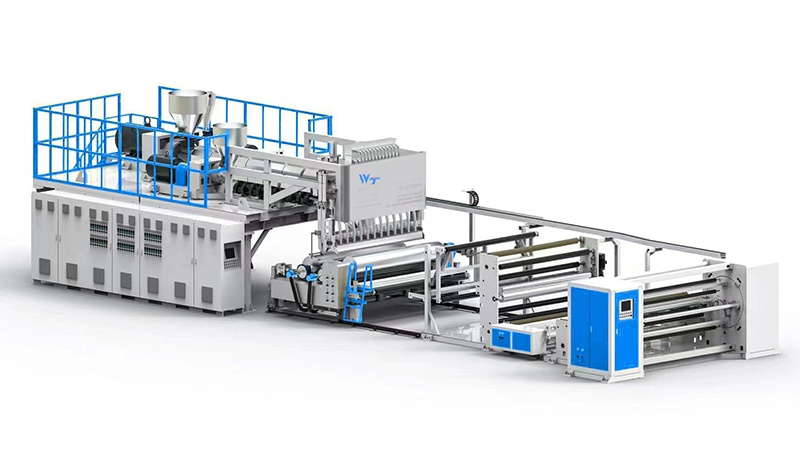

2400MM Full-Automatic Stretch Film Production Line

2400MM Full-Automatic Stretch Film Production Line

-

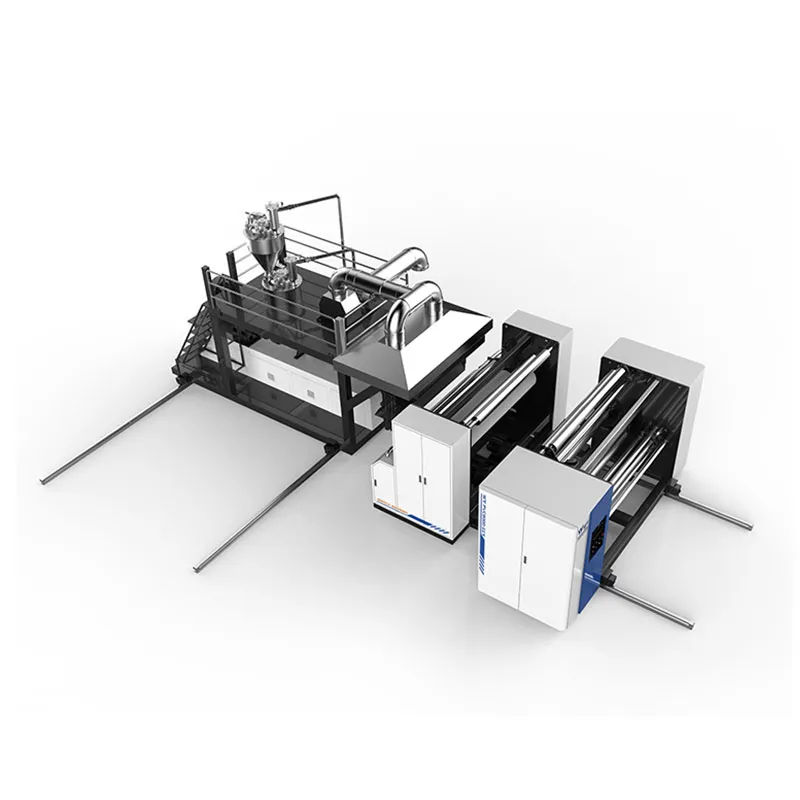

1850MM Three Five Layer Co-extrusion Stretch Film Production Line

1850MM Three Five Layer Co-extrusion Stretch Film Production Line

-

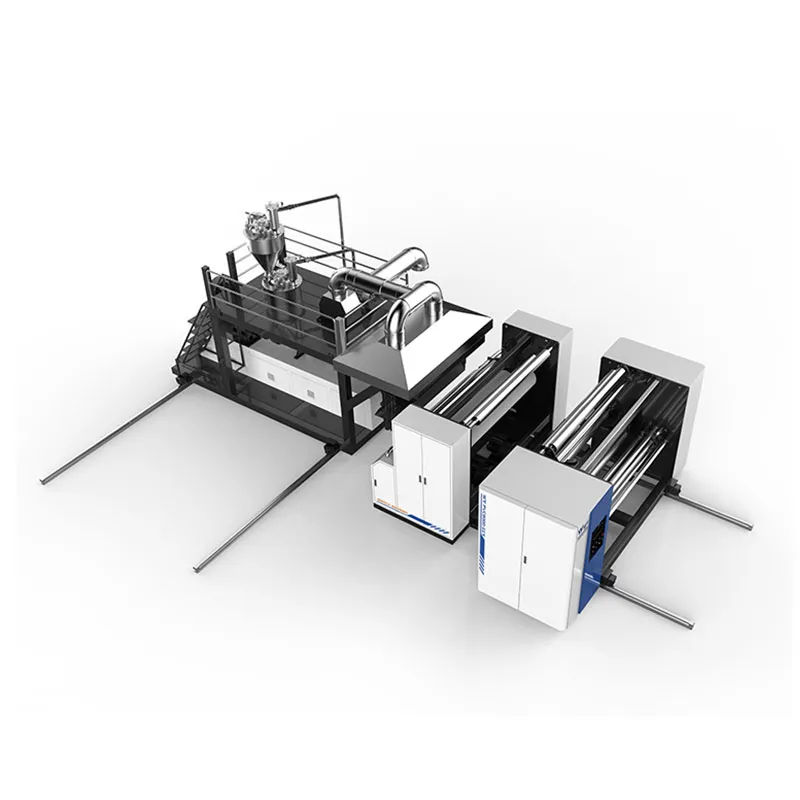

1250mm Automatic High Speed Three/Five Layer Co-extrusion Stretch Film Production Line

1250mm Automatic High Speed Three/Five Layer Co-extrusion Stretch Film Production Line

-

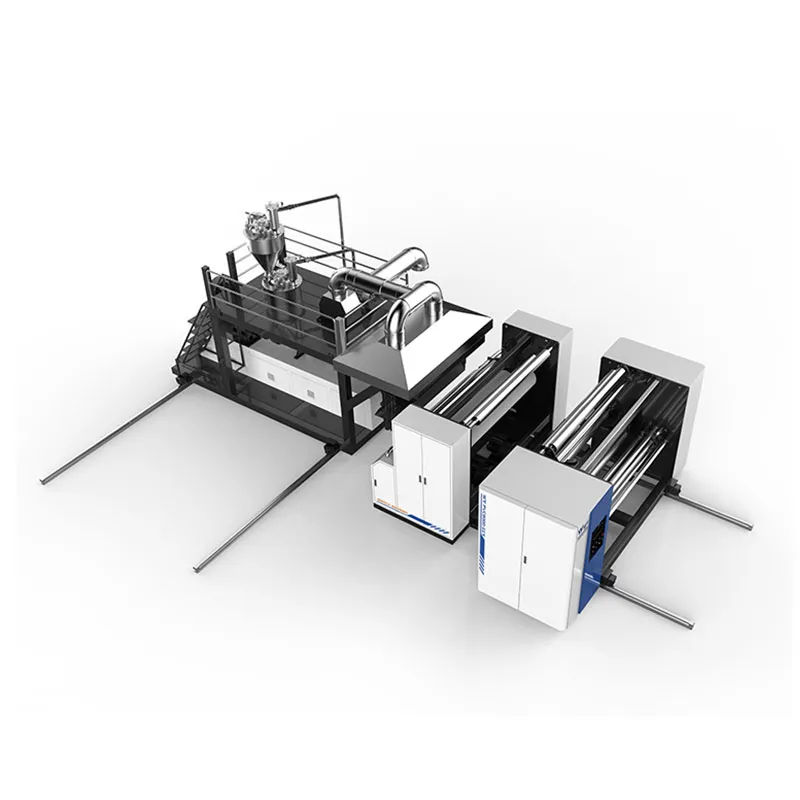

1250MM Fully Automatic High Speed Two/Three-layer Stretch Film Machinery

1250MM Fully Automatic High Speed Two/Three-layer Stretch Film Machinery

-

Four-Shafts Roll Change Automatic Cast Stretch Film Production Line

Four-Shafts Roll Change Automatic Cast Stretch Film Production Line

-

New Three-Shafts Automatic Stretch Film Production Line

New Three-Shafts Automatic Stretch Film Production Line

-

Full-Automatic Back Rest Stretch Film Production Line

Full-Automatic Back Rest Stretch Film Production Line

-

2400MM Cling Film Production Line

2400MM Cling Film Production Line

-

1850MM Cling Film Production Line

1850MM Cling Film Production Line

-

1250MM Cling Film Production Line

1250MM Cling Film Production Line

-

Fully Automatic Stretch/Cling Film Rewinding Machine

Fully Automatic Stretch/Cling Film Rewinding Machine

-

Semi-automatic High Speed Aluminum Foil Rewinding Machine

Semi-automatic High Speed Aluminum Foil Rewinding Machine

-

High Speed Pre Stretch/Cling Film Rewinding Machine

High Speed Pre Stretch/Cling Film Rewinding Machine

-

Semi-automatic Stretch/Cling Film Rewinding and Slitting Machine

Semi-automatic Stretch/Cling Film Rewinding and Slitting Machine

-

New Design Fully Automatic High Speed Rewinding Machine

New Design Fully Automatic High Speed Rewinding Machine

-

Five Shafts Fully Automatic Stretch/Cling Film Rewinding Machine

Five Shafts Fully Automatic Stretch/Cling Film Rewinding Machine

WHAT ARE YOU LOOKING FOR?